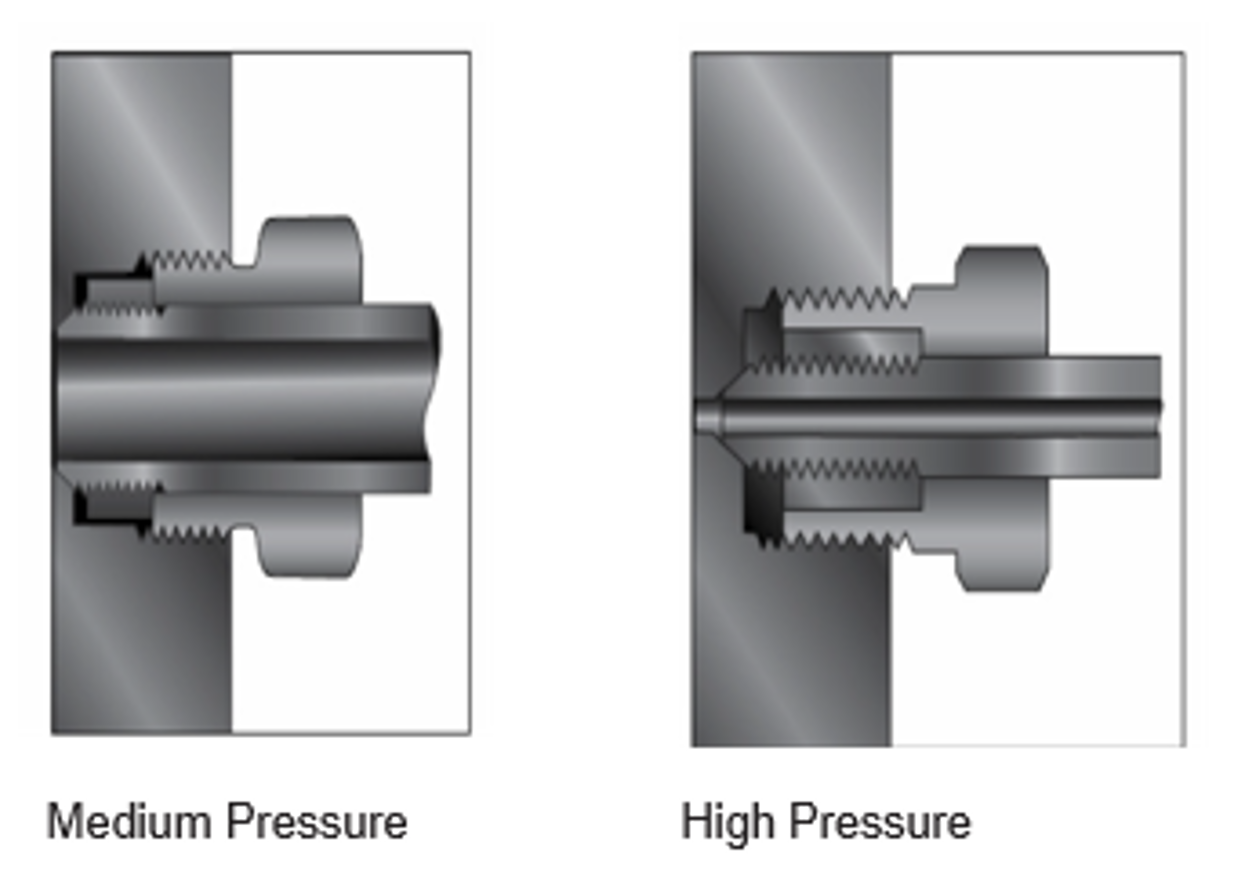

Sealing Method

Unlike twin ferrule fittings that are made up with rotational geometry, coned band threaded connections are made up to a specific torque, installer must use a calibrated torque wrench.

NOTE

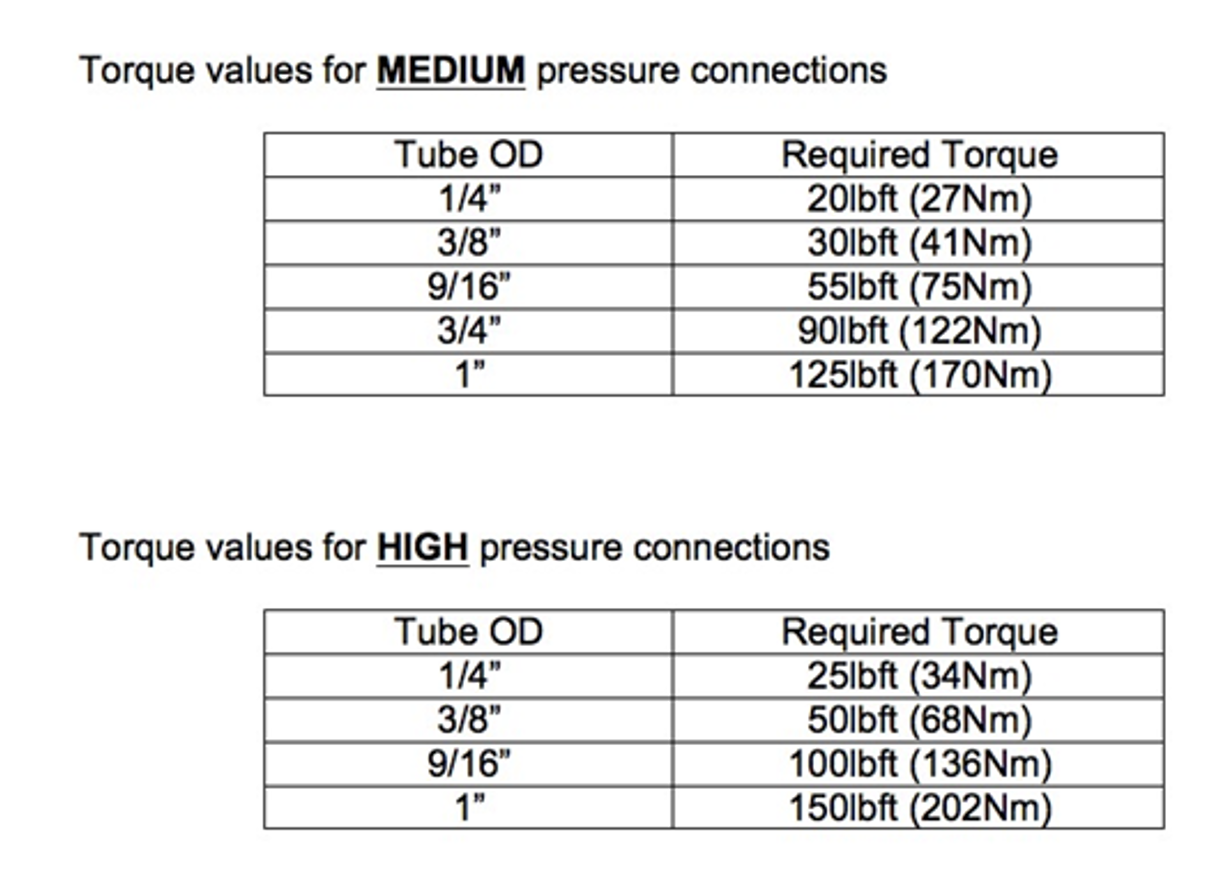

Medium and high-pressure connections are made up to different torques.

See tables:

Imagine a clock face around the nut, mark the nut at the 6 o’clock position

Assembly and Makeup of Connection

- Lubricate all contact areas (cone, collar where it contacts the gland nut & gland nut threads) with thread lubricant. Place gland down tubing, turn down the collar on tubing until one to two threads are exposed between collar and cone.

- Insert tubing in the connection, push gland into thread and tighten “fingertight”.

- Tighten to specified torque figure (see chart) using a calibrated torque wrench. Remember to hold the fitting body steady when torqueing the gland, this can be done using an additional wrench.